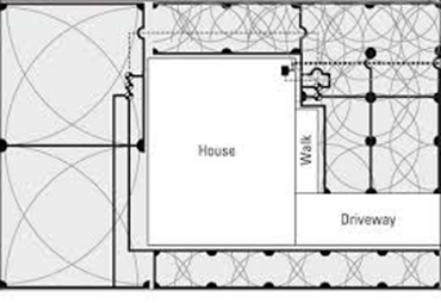

SIZE:

DRIVEWAYS

Driveway lengths:

Generally plan your driveways using 18-20 feet of length for each car or truck. Allow 22-24 feet for full size pickups with extended cabs and oversized mini-vans. If at all possible, allow three to five feet of “walk around” room at the bottom of the driveway.

Driveway widths:

For each vehicle, plan a minimum of 10 feet of width. If space allows, use wider spacing for easier walk-about space between vehicles, the driveway, and the sidewalk, and the vehicles and the garage or house. Picture kids removing their bicycle from the garage and allow enough space between vehicles to avoid a scratched car.

- Single Driveway: 20x10 minimum. Minimum width 10 feet, preferred 12 feet to allow car doors to open and step onto pavement

- Double Driveway: 20x20 minimum, 20x24 is preferred

- Triple Driveway: 20x30 minimum

Emergency and delivery vehicle access may also be a consideration in the design of a new driveway, especially on longer driveways.

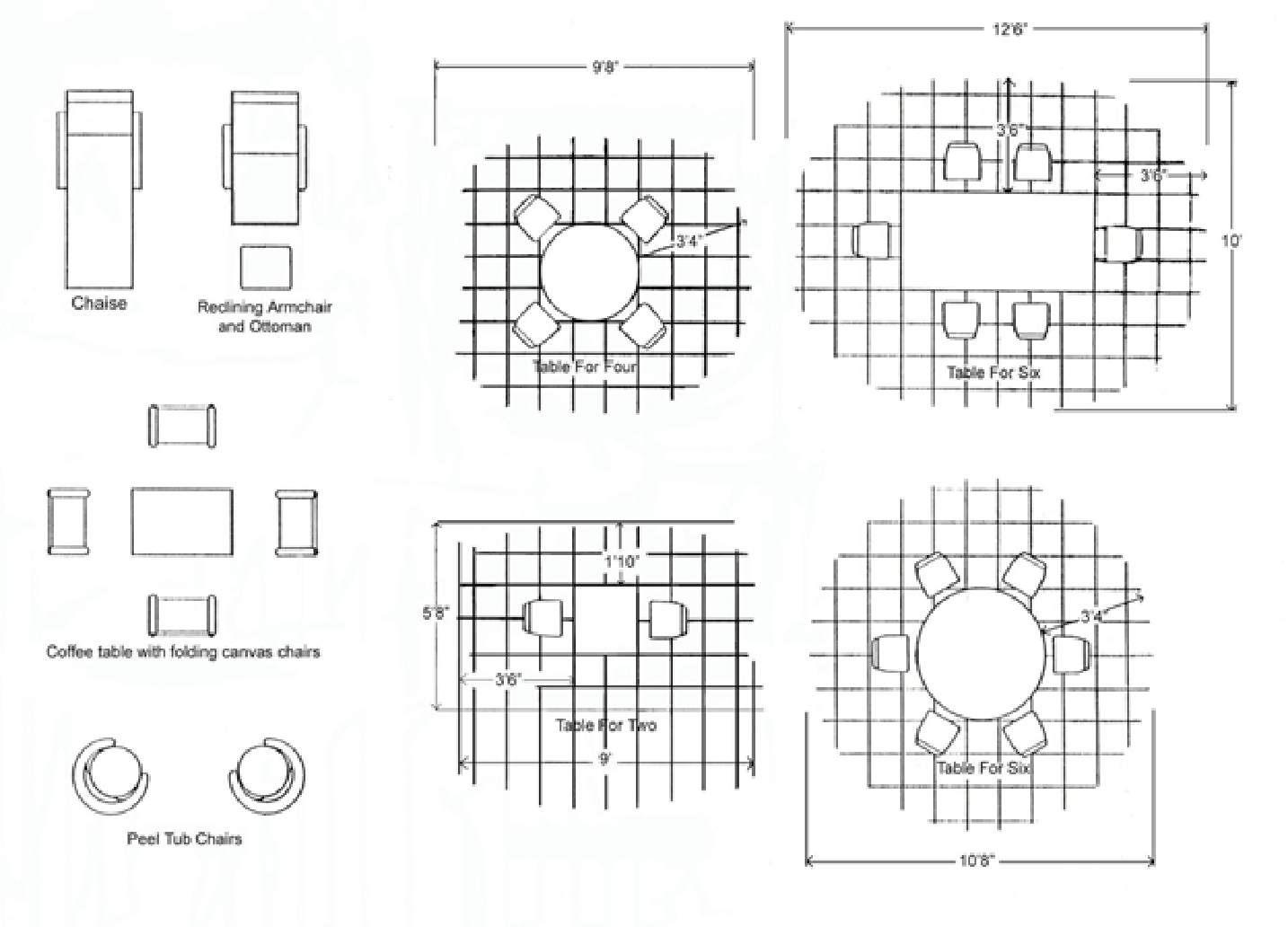

PATIOS

FINISH:

Finish Options

Concrete is known as a versatile construction material that is used worldwide for many residential, commercial, and industrial applications. What makes this material unique is that it carries strength on the inside and displays beauty on the outside. The concrete’s exterior appearance is modified through the use of various products or techniques.

Broom Finish - Standard

A broom finish can be applied to make concrete surfaces slip-resistant. This is done after placement, leveling, and troweling of concrete. Once a smooth surface is created, a broom is dragged across the surface of the concrete to create small ridges. This finish provides traction control, particularly when the concrete surface is wet. Concrete surfaces without a broom finish tend to be slippery and can be dangerous when wet. A picture frame border is a popular upgrade to this type of finish.

Slick Troweled - Standard on floors and covered porches

Slick troweled concrete is created by either a steel hand trowel or trowel machine used by a cement mason to close the exposed surface of the concrete. Typically, slick troweled concrete can be found in a garage, basement, or warehouse floors and covered front porches. Slick troweled concrete is a good choice for garages and porches because it is easy to clean.

More labor and time are required to produce a slick troweled concrete finish since it takes time for the concrete to harden enough for the cement finisher to walk or kneel on and to trowel the surface. When the concrete becomes hard enough to stand or kneel on – there is a limited window of time the finisher has to ‘close the surface’ before the concrete hardens beyond being able to be worked.

Mag Swirl

In our opinion, a Mag Swirl finish is one of the most aesthetically pleasing types of concrete finish. There is a tremendous amount of skill and craftsmanship needed to execute this type of finish. Mag Swirl is generated by smearing the concrete surface in a uniformly overlapping circular pattern beginning at the last round of floating by moving the trowel in swirls or circles. There are several patterns or designs available with this finish as the depth and shape of swirl finish can be changed as per your individual preferences.

This type of finish is favored for outdoor applications because not only does it add visual appeal to the surface, but it also provides more grip than a smooth surface finish, especially in wet conditions. Common Mag Swirl finish applications include driveways, patios, and sidewalks.A picture frame border is a popular upgrade to this type of finish

Exposed Aggregate Finish

Once commonly found in sidewalks of old cities, an exposed finish is created by washing the top layer of concrete away, which exposes the edges of the natural stone aggregates that are mixed into the concrete. This provides an attractive and slip-resistant finish.

In addition to the use of the normal concrete materials (cement, sand, gravel, and water), other materials may be added into the mix to provide exposed finishes with unique looks. Examples are rose quartz, limestone, dark gray or black basalt, red or blue granite, and even colored glass or seashells. The key with any of these additives is to avoid materials containing iron, which can stain the concrete. It’s also important to provide a high-quality seal after concrete curing in order to protect the surface.

Common Missouri Aggregate Rock Options:

- Old Monroe Torpedo - A multi-colored 3/8”gravel from the Old Monroe Deposit, located in Old Monroe, Missouri.

- Iowa Glacial

- Illinois Glacial

- Meramec Torpedo - Located at approximately the 14 mile mark of the Meramec River, a tributary of the Mississippi River, this alluvial deposit consists of about half sand and half gravel, and is of glacial origin. Color ranges from light grey to buff to yellow and brown. The larger natural aggregate shape is rounded and smooth.

Concrete stamps are a common method of texturing concrete. These stamps are comprised of panels with inlaid designs, which are placed on concrete while it is still curing. Designs may consist of brick, stone, wood, or other decorative patterns to provide the desired look, sometimes mimicking other common building materials, but retaining the strength and durability of concrete. Generally stamped concrete is colored by adding color pigments to the concrete mix in addition to a secondary color (release) pigment that is added during stamping. Regular sealing of this type of finish helps longevity of the color.

Stamp Options:

Our Favorite Patterns

Majestic Ashlar Slate

Seamless Belgium Slate

Appalachian Flagstone

Cobblestone

Random Fieldstone

Stamp Border Options:

Options:

Color Option

Color Selection (For Stamped Concrete)

Our Favorite Colors: Brick Red, Coral Buff, Gull Gray, Sienna, Soapstone

Acid Stain Color Selection (For Slick Finished Floors)

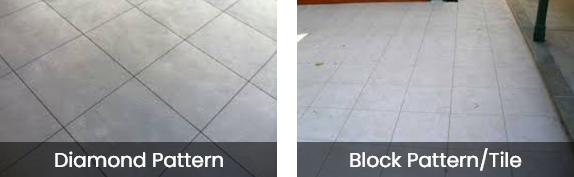

Decorative Saw Cutting Options:

These decorative saw cutting patterns are not only functional in serving as control joints to help prevent cracks, they are also a versatile option to produce a truly custom project.

All patterns are available in 3-6 foot grids.

Fire Pit Options (with patios)

We offer three-block fire pit options through our local vendor, Midwest Block & Brick: